TUBE LASER CUTTING

TUBE LASER CUTTING

For the laser processing using a LASERTUBE LT7 BLMGROUP replacing all the work carried out on different machines in sequence, such as cutting to length, deburring, punching, stamping, drilling and milling. It allows you to get a piece tubular finished in one process. Thanks to the tilting cutting head, it is possible to make chamfers, semi-chamfers and flares. In addition to round, square, rectangular, flat oval, flat oval and semi-elliptical, you can create different sections by programming in CAD-CAM.

This technology is used both for processing for third parties for internal machining of finished products.

Thanks to the software CAD/CAM ARTUBE you can:

- The design and generation of machine tubular components or wireframe of the structure;

- Management of special sections;

- The management of open profiles;

- Importing 3D files .IGS/.X_T/.STP of individual components and frames.

Technical features

Round tube: min. 12 - max. 152,4 mm (6")

Square tube: min. 12x12 - max. 152,4x152,4 mm (6"x6")

Rectangular: side min. 12 mm – max 150 mm

Open and special profiles

Material machined: steel, stainless steel, aluminum, copper and brass.

Weight bar up to 23 kg/m (15.5 lb/ft)

Bundle bar loading min. 2 - max. 6,5 m

Single bar unloading max. 4,5 m

Beam loader capacity 4000 kg

Fiber laser source 3 kW

Laser tube cutting machine LT7 LASERTUBE BLMGROUP

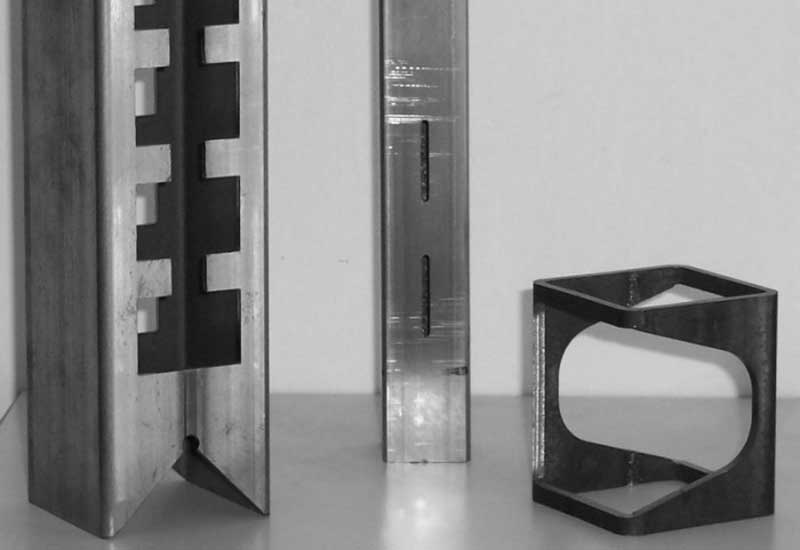

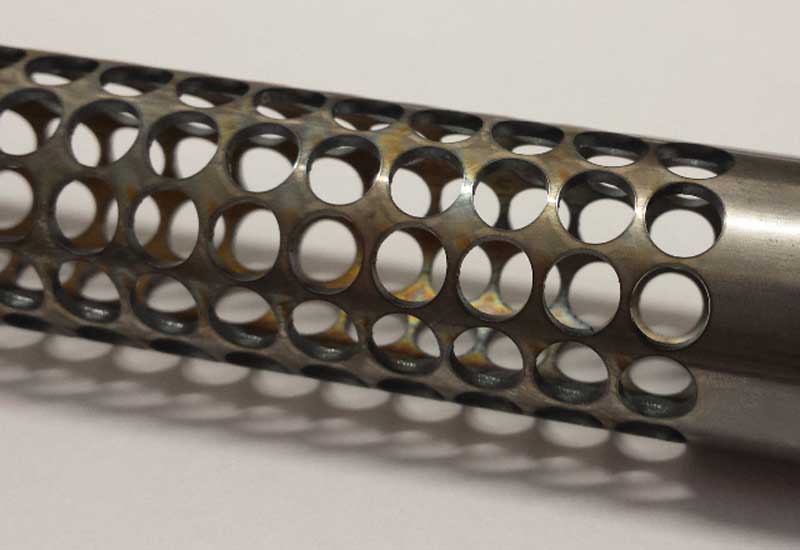

Example of processing

Example of processing

Example of processing

Example of processing

.jpg)

Example of finished product using technique of "cutting and crease"

.jpg)

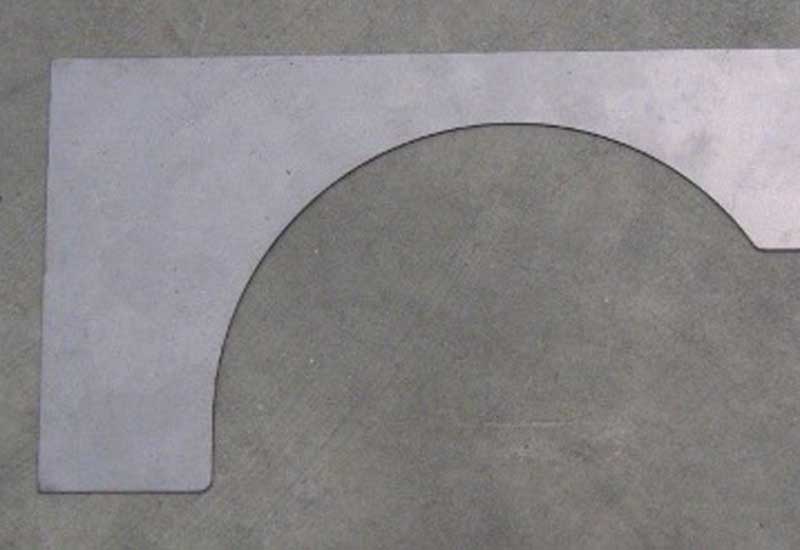

Example of sheet metal processing

.jpg)

Example of sheet metal processing

Example of sheet metal processing